Центробежный насос — это механическое устройство, преобразующее энергию вращения рабочего колеса в кинетическую энергию жидкости для транспортировки. Центробежные насосы Центробежные насосы широко используются в таких отраслях, как водоподготовка, нефтегазовая промышленность, химическая переработка и системы отопления, вентиляции и кондиционирования воздуха, и являются ключевым оборудованием для эффективной транспортировки жидкостей. В этой статье мы рассмотрим принцип работы центробежных насосов, их основные компоненты, различные типы и области применения, чтобы помочь вам получить полное представление о том, что такое центробежные насосы. Читайте дальше, чтобы узнать больше!

Принцип работы центробежного насоса заключается в том, что электродвигатель приводит рабочее колесо во вращение с высокой скоростью, что приводит к образованию вращающегося потока жидкости внутри насоса и созданию высокой кинетической энергии на выходе из рабочего колеса. Под действием центробежной силы жидкость течёт вдоль корпуса насоса к выходу или перекачивается к рабочему колесу следующей ступени. Одновременно в центре рабочего колеса, благодаря оттоку жидкости, образуется зона низкого давления, создающая разность давлений с давлением жидкости во всасывающем отверстии, что обеспечивает непрерывное поступление жидкости в корпус насоса. По мере вращения рабочего колеса насос обеспечивает непрерывное всасывание и нагнетание, завершая процесс транспортировки жидкости.

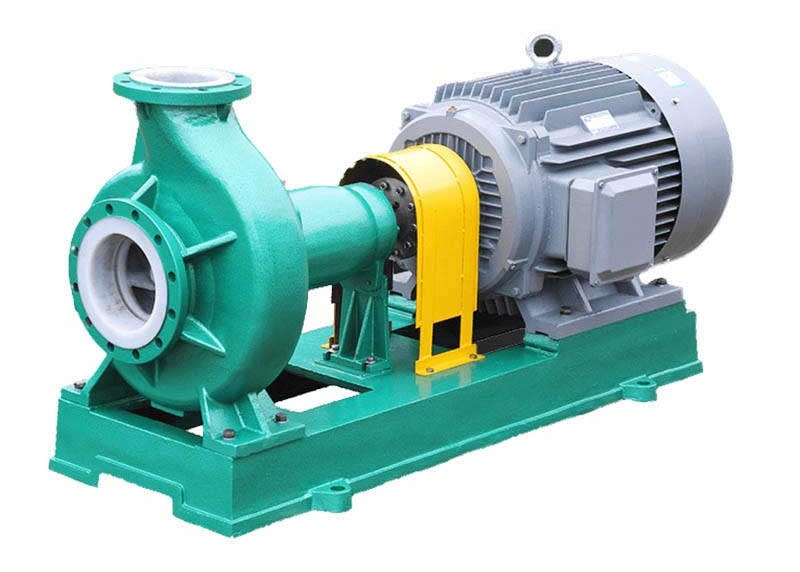

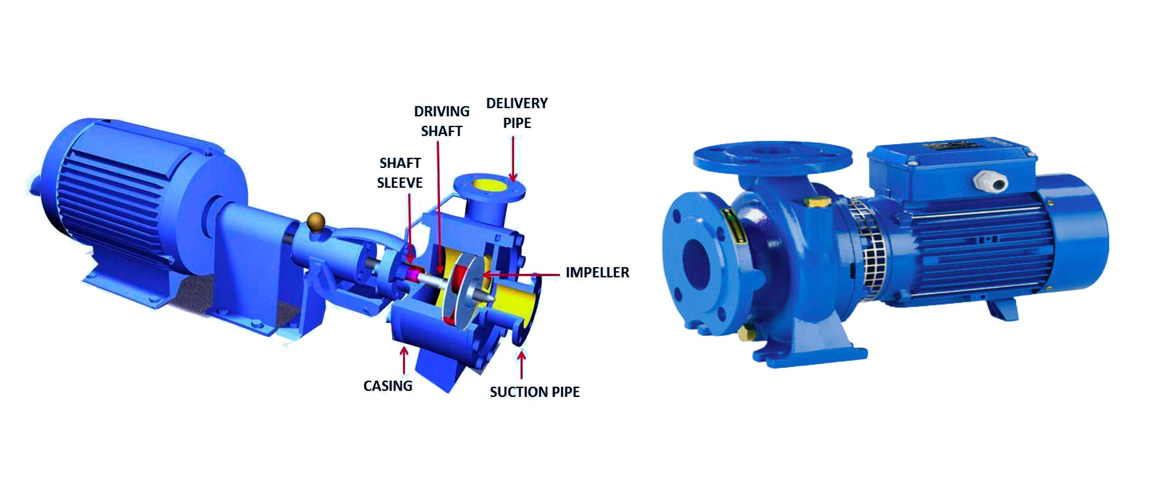

The детали центробежного насоса В состав основных компонентов входят рабочие колеса, корпуса насосов, валы насосов, подшипниковые узлы, уплотнительные устройства, всасывающие и напорные патрубки, а также приводные двигатели. Ниже приведены функциональные характеристики каждого компонента:

Рабочее колесо: Рабочее колесо — это вращающийся элемент, который передает кинетическую энергию жидкости, создавая центробежную силу для перемещения жидкости наружу.

Корпус насоса: корпус охватывает рабочее колесо и направляет поток жидкости от рабочего колеса к выпускному отверстию, преобразуя скорость в давление.

Вал: Вал передает механическую энергию от двигателя к рабочему колесу, поддерживая стабильное вращение и выравнивание.

Подшипниковый узел: подшипники поддерживают вал и уменьшают трение, обеспечивая плавную и точную работу.

Механическое уплотнение или набивка: предотвращает утечку жидкости вдоль вала в месте выхода из корпуса.

Всасывающий и нагнетательный патрубки: всасывающий патрубок позволяет жидкости поступать в насос, а нагнетательный патрубок выводит ее под давлением.

Двигатель или привод: двигатель обеспечивает необходимую мощность для вращения рабочего колеса и запуска процесса перекачки.

Промышленные центробежные насосы представлены в различных конструкциях и моделях для различных промышленных применений. Ниже приведены некоторые распространённые типы:

Насосы с магнитным приводом: используют герметичную технологию магнитного привода, подходящую для транспортировки легковоспламеняющихся, взрывоопасных или токсичных сред (таких как растворители, жидкий хлор).

Полупогружные насосы: двигатель находится над поверхностью жидкости, что подходит для применений со значительными колебаниями уровня воды (например, дренажные станции, временная борьба с наводнениями).

Самовсасывающие насосы: оснащены функцией выпуска воздуха, что исключает необходимость ручной заливки, подходят для периодического всасывания (например, балластировка судов, осушение строительных площадок).

Мембранные насосы: используют возвратно-поступательное движение мембраны для транспортировки высоковязких или содержащих твердые частицы жидкостей (например, суспензии, краски).

Водяные насосы: Универсальная конструкция для транспортировки чистой воды (например, муниципальное водоснабжение, сельскохозяйственное орошение).

Кислотные насосы: Изготовлены с использованием коррозионно-стойких материалов (например, ПВДФ, Хастеллой), специально разработанных для кислых сред (например, серной кислоты, соляной кислоты).

Щелочные насосы: Оснащены специальными уплотнениями и технологиями обработки материалов, подходят для сильных щелочных жидкостей (например, гидроксид натрия, электролит).

Промышленные центробежные насосы широко используются во многих отраслях промышленности:

Водоснабжение и водоотведение: Передача чистой воды, сточных вод и ливневых вод на очистные сооружения.

Нефть и газ: транспортировка сырой нефти, нефтеперерабатывающих жидкостей и морской воды при морских операциях.

Химическая и фармацевтическая промышленность: работа с едкими кислотами, растворителями и стерильными фармацевтическими жидкостями.

Электростанции: циркуляционная питательная вода котлов, охлаждающая вода и конденсат при производстве энергии.

Горнодобывающая промышленность и производство: перекачка абразивных шламов и промышленных охлаждающих жидкостей.

Сельское хозяйство: эффективное распределение поливной воды и агрохимикатов.

Высокая эффективность: разработаны для оптимального преобразования энергии, обеспечивая превосходную скорость потока при минимальном потреблении энергии.

Низкие эксплуатационные расходы: упрощенная механическая конструкция с единственным вращающимся компонентом (рабочим колесом) снижает износ и потребность в обслуживании.

Компактность: вертикальные/горизонтальные конфигурации, экономящие пространство, адаптируются к ограниченным промышленным пространствам.

Универсальность материала: доступны варианты из нержавеющей стали, чугуна, фторопласта и современных полимеров для работы с агрессивными/абразивными средами.

Работа без пульсаций: непрерывное вращательное движение обеспечивает плавную передачу жидкости без вибраций, что критически важно для точных процессов.

Центробежные насосы универсальны, высокоэффективны и широко применяются, что делает их основным оборудованием современных систем подачи жидкостей. Как профессиональный поставщик насосных решений, мы специализируемся на удовлетворении особых потребностей в перекачке жидкостей в различных отраслях промышленности и предлагаем комплексные индивидуальные услуги. Если вам требуется оптимальное решение для ваших условий эксплуатации, свяжитесь с нашими техническими специалистами для получения консультации.

Наши часы

Пн, 21 ноября – Ср, 23 ноября: 9:00 – 20:00.

Чт, 24.11: закрыто. С Днем Благодарения!

Пт, 25 ноября: 8:00–22:00.

Сб 26.11 – Вс 27.11: 10:00 – 21:00

(все часы по восточному времени)