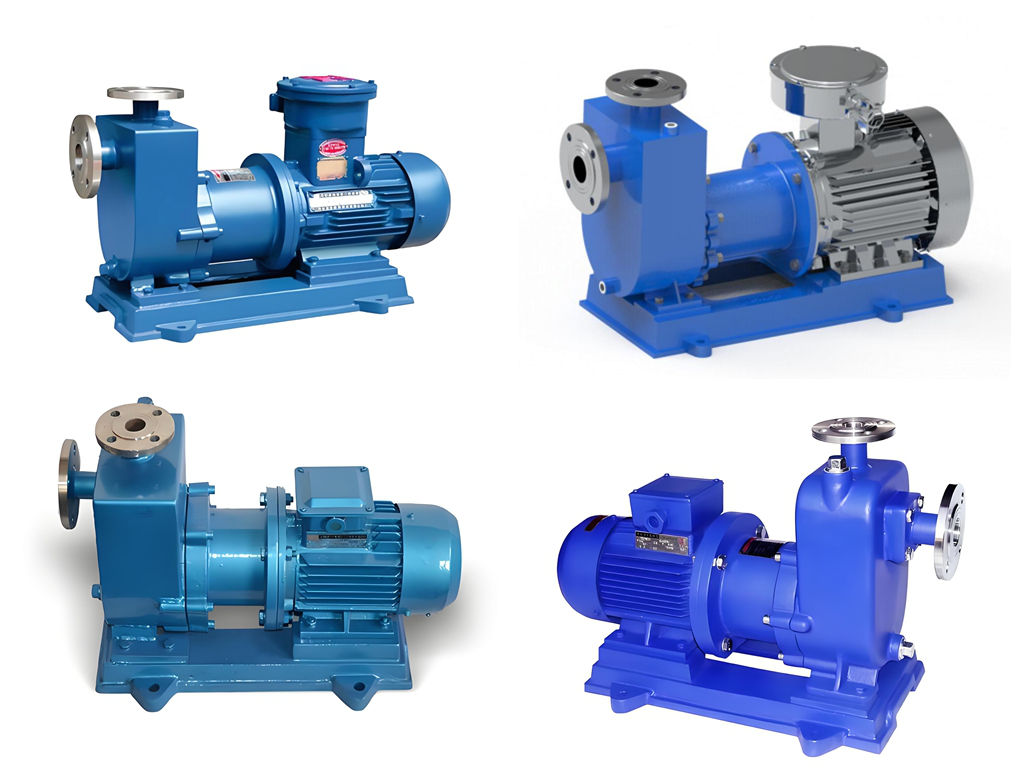

The CQZ Stainless Steel Self-Priming Magnetic Drive Pump is a specialized centrifugal pump that combines magnetic drive technology with self-priming functionality. It replaces the traditional dynamic seal design with a static seal, ensuring a completely sealed pump flow path and eliminating the risk of media leakage.

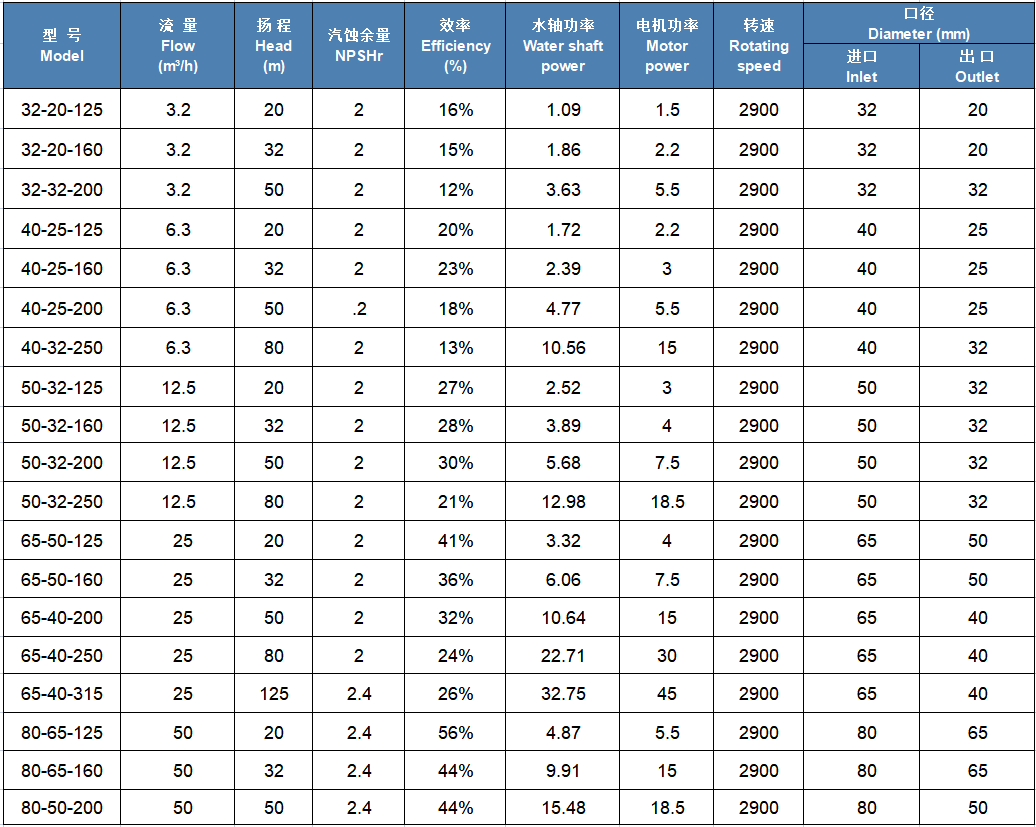

Максимальный поток :

3m³/h~800m³/hМаксимальный напор :

12.5m~130mМаксимальная мощность :

0.37~18.5KwТемпература :

-120℃~320℃Материал :

304、304L、316L、2205/904L、TA2、HC276

CQZ Stainless Steel Self-Priming Magnetic Drive Pump integrates the self-priming capability of the CQ magnetic drive pump, eliminating the need for a foot valve installation or pre-filling with water before startup, thereby simplifying the operation process. Its working principle involves an external magnet driving an internal magnet to rotate the impeller, rapidly venting air and creating a vacuum during the self-priming process to achieve highly efficient self-priming.

The CQZ Self-Priming Magnetic Drive Pump is widely used for transporting corrosive media in chemical, pharmaceutical, electroplating, and environmental protection industries. It is particularly suitable for handling flammable, explosive, toxic, or valuable liquids, serving as an energy-efficient, safe, and reliable fluid transfer solution.

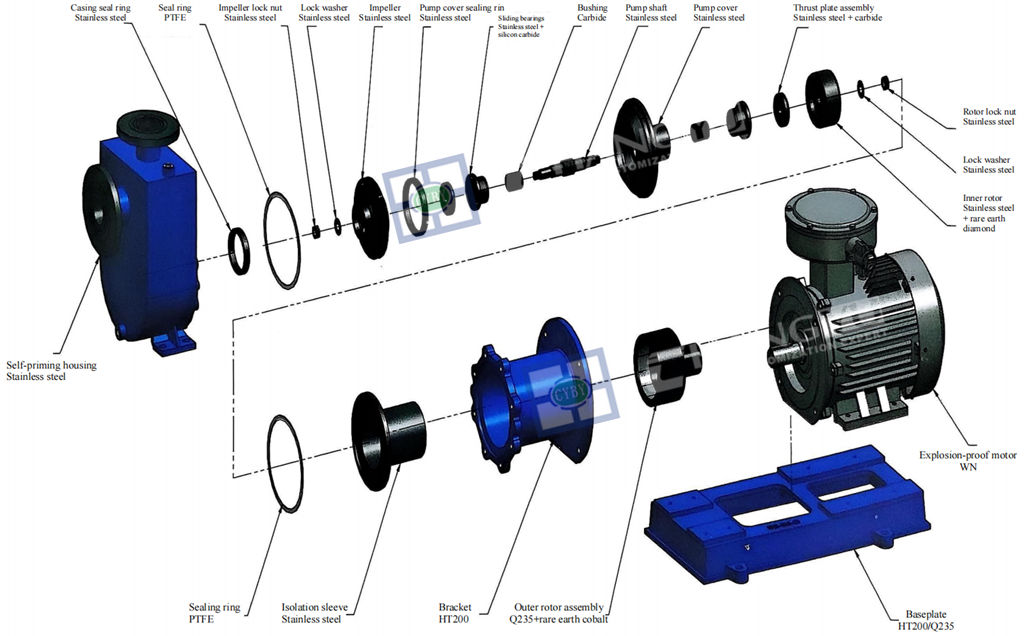

The CQZ Stainless Steel Self-Priming Magnetic Drive Pump primarily consists of a magnetic drive assembly (inner and outer magnet assemblies), pump body, impeller, isolation sleeve, and supporting structural components. The magnetic drive system enables non-contact power transmission. The impeller and flow passages are constructed from corrosion-resistant materials. The isolation sleeve positioned between the inner and outer magnets creates a fully sealed environment, ensuring zero leakage of the pumped medium.

The working principle of the CQZ magnetic self-priming pump is based on magnetic coupling transmission for non-contact power transfer. The motor drives the outer magnetic steel assembly to rotate. The magnetic field penetrates the isolation sleeve, driving the inner magnetic steel and impeller to rotate synchronously. During the self-priming phase, the high-speed rotation of the impeller creates a vacuum within the pump chamber, automatically drawing in liquid and completing the delivery process. Please see the video below for details:

CQZ Magnetic Self-Priming Pumps feature leak-free operation, corrosion resistance, and high safety, making them widely applicable in the following fields:

To provide you with an accurate quote and optimal solution, please supply the following technical information:

Medium Properties: Specify the exact name, concentration, temperature, viscosity, and particle content (particle size and concentration) of the conveyed medium.

Operating Parameters: Flow Rate: ____ m³/h, Head: ____ m, Self-priming Height: ____ m

Operating Conditions: Working Temperature ___℃; Inlet Pressure ___MPa; Installation Environment (Indoor/Outdoor, explosion-proof requirements, etc.).

Material Requirements: Based on the corrosiveness of the medium, specify material preferences for wetted components such as the pump body and isolation sleeve (e.g., 304, 316L, Hastelloy, etc.).

Required Connections: Inlet diameter: _____, Outlet diameter: _____

Connection method: (e.g., flange standard, thread specification).

By providing the above information, our engineers will tailor a customized solution and provide a prompt quotation.

As China's leading professional supplier and manufacturer of self-priming magnetic drive pumps, Changyu Pump possesses robust technical expertise, state-of-the-art production equipment, and a comprehensive product portfolio. We specialize in providing corrosion-resistant, leak-free, and high-safety industrial pump solutions. Our product portfolio encompasses 14 major series and over 100 varieties, including PTFE-coated magnetic drive pumps, stainless steel self-priming magnetic drive pumps, corrosion-resistant centrifugal pumps, and slurry pumps. These are suitable for diverse special media and environments across industries such as petroleum, chemical, pharmaceutical, electroplating, and environmental protection.

The company holds ISO 9001 international quality management system certification, with products compliant with CE, ATEX, EAC, API, and other international standards. We possess nearly 25 core technology patents. We are committed to delivering highly reliable, long-lasting, and energy-efficient pumping equipment, offering customized solutions tailored to specific operational conditions.

For detailed product information, technical selection support, or customized solutions, please contact us at any time. Our team of engineers will promptly provide professional assistance.

Наши часы

Пн, 21 ноября – Ср, 23 ноября: 9:00 – 20:00.

Чт, 24.11: закрыто. С Днем Благодарения!

Пт, 25 ноября: 8:00–22:00.

Сб 26.11 – Вс 27.11: 10:00 – 21:00

(все часы по восточному времени)